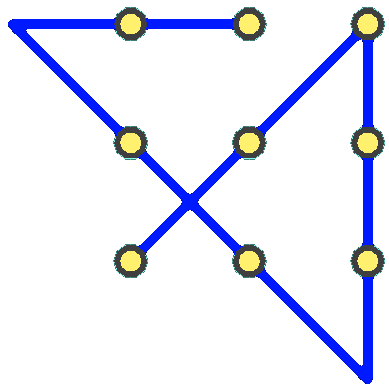

We developed an ultra low cost, high performance AOI machine that automatically inspects safety critical PCBs for a client. It inspects panels within 50ms, then it programs and verifies the firmware in four microcontrollers concurrently within 450ms. All pass/fail and tracking data is recorded. A bent, missing, reverse of badly soldered component is highlighted on the screen. It has been running for over ten years, without any problems except for the occasional probe replacement. We also developed vision inspection robots used in the manufacturing of GM’s Holden Commodore instrument clusters. We can apply similar low cost innovative technology to help you out.